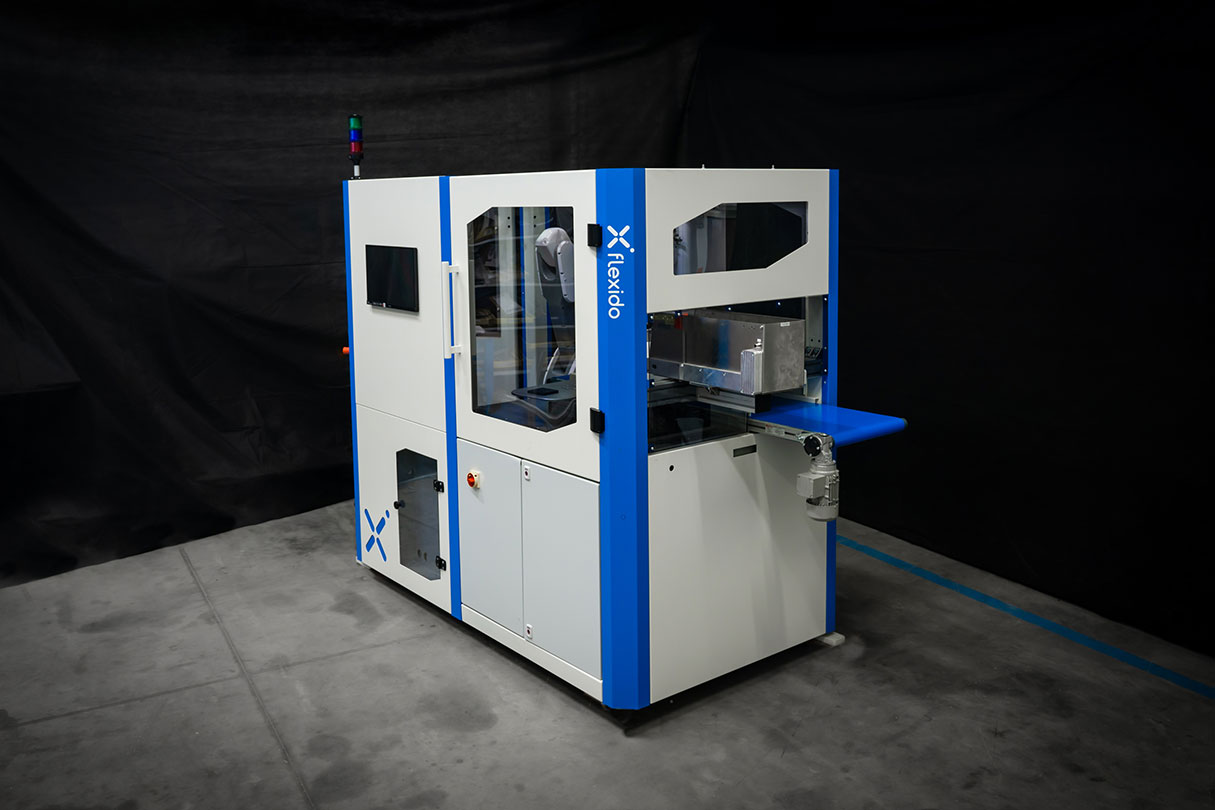

FLEX 25/50

Standard Robotic Cell

FLEX 25/50 is a high-capacity robotic cell meticulously designed for complex industrial applications. Ideal for demanding tasks in insertion and injection molding, this advanced solution excels in high-performance environments, offering unparalleled automation capabilities that bring a strategic advantage to your operations.

Key Features:

- Dimensions (L x W): 2160 x 1120 mm to 2500 x 2360 mm + safety fence

- Robots: MZ 10 LF / MZ 12, MZ25, MZ50F

- Payload: 10 / 12 kg, 25 kg, 50 kg

- Reach: 1202 / 1404 mm, 1882 mm, 2102 mm

- Integrated conveyor belt for efficient part handling

- Interface for E67, E78, E73 for broad compatibility with various industrial machines

Applications:

- Complex insert placing & insert molding

- Advanced pre-injection molding applications (e.g., insert laser cleaning)

- Intricate post-injection molding applications (e.g., laser engraving)

- Comprehensive quality control

Options:

- Bowl feeder with sorting unit for insert feeding

- Vibratory bowl feeder for organized feeding and sorting

- Infeed and outfeed systems: Conveyor with 2D camera, vibrating feeder plate, etc.

- Vision system for meticulous quality checks

- Insert preparation table with options for preheating using hot air or induction

- Tray stacker: Various configurations for high capacity and efficient handling

Automation for Complex Applications

Automation in complex injection molding and insertion tasks is essential for maintaining high standards of quality and efficiency. FLEX 25/50 is engineered to handle sophisticated processes with precision, speed, and reliability, ensuring superior product quality and maximizing added value.Benefits of Automation in Complex Applications:

- Enhanced Productivity: Automated systems operate continuously, significantly increasing production volumes and reducing cycle times.

- Precision and Consistency: High-precision robotics minimize errors, ensuring consistent quality and reducing waste.

- Cost Efficiency: Lower labor costs and minimized error-related expenses contribute to substantial savings.

- Improved Safety: Robots handle hazardous tasks, reducing the risk of injuries and improving workplace safety.

- Competitive Edge: Automation enables rapid adaptation to market demands and supports the production of highly customized products efficiently.

Why Choose FLEX 25/50?

- Designed for Complexity: Perfect for handling sophisticated tasks requiring high precision and reliability.

- Robust Performance: Built for long-term, continuous operation with minimal maintenance, ensuring consistent output.

- Versatile and Flexible: Adapts seamlessly to various industrial requirements, enhancing operational efficiency and profitability.

- Compact Footprint: Despite its advanced capabilities, FLEX 25/50 maintains a space-efficient design, suitable for diverse industrial environments.