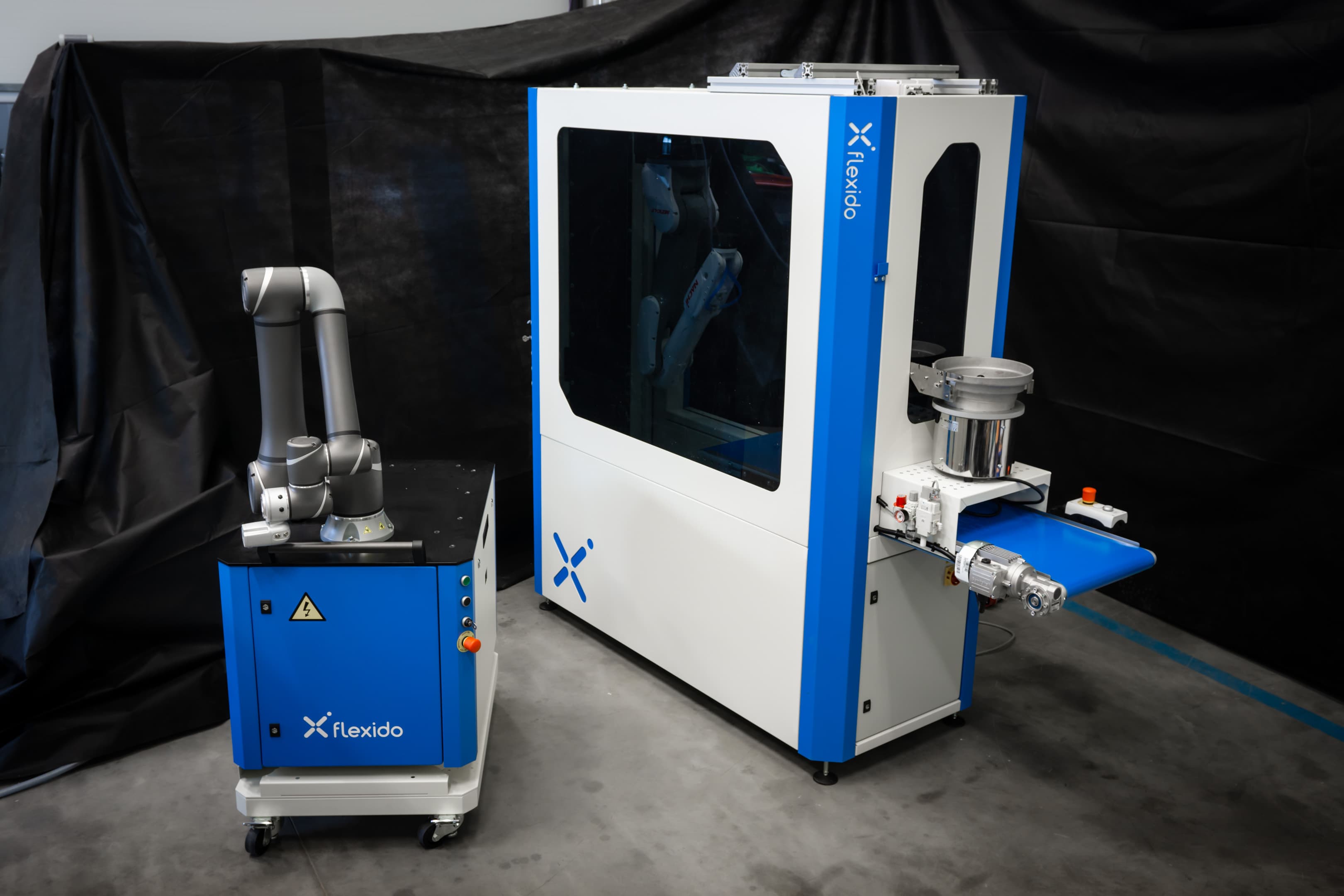

Flex 7 IMM

Standard Robotic Cell

FLEX 7 IMM is a robotic cell designed for high performance and increased added value in industrial processes, particularly in part insertion and injection molding. It provides a strategic advantage through automation and enhanced productivity.

Enter into world of 6-axis robots

Affordable solution with small footprint

Key Features:

- Dimensions (L x W): 1660 x 720 mm

- Robot: MZ 7L / 10FL

- Payload: 7 kg / 10 kg

- Reach: 911 mm / 1202 mm

- Integrated conveyor belt for efficient part handling

- Interface for E67, E78 / E73 for broad compatibility with various industrial machines

- Vision system for precise quality control

- Grippers for 6-axis and Skara robots for flexibility in handling different parts

Applications:

- Unloading and ejection of parts

- Quality control

- Simple insert placing & insert molding

Options:

- Integrated Skara robot for insert sorting

- Bowl feeder for insert preparation

- Vision system for quality check

- Insert preparation table

Automation for Higher Added Value in Injection Molding

Automation in injection molding is no longer just a trend but a necessity for companies aiming to stay competitive. The FLEX 7 IMM robotic cell optimizes the production process with greater precision, speed, and consistency. This not only boosts productivity but also enhances the quality of final products, resulting in higher added value.

Benefits of Automation in Injection Molding:

- Increased productivity: Automated systems operate continuously, increasing production volume and reducing manufacturing time.

- Fewer errors: Robotic precision minimizes the risk of errors, leading to fewer rejected parts and less waste.

- Cost reduction: Reduced need for manual labor lowers labor costs, and decreased error rates cut costs related to scrap and rework.

- Enhanced safety: Robots take over hazardous tasks, reducing the risk of worker injuries.

- Competitive advantage: Automation allows for quicker response to changes in demand and the production of highly customized products at competitive prices.

Why Choose FLEX 7 IMM?

- Automation: Automating simple and repetitive tasks reduces costs and increases productivity.

- Reliability: Our robots are designed for continuous operation with minimal maintenance requirements.

- Flexibility: FLEX 7 IMM adapts to various industrial needs, enhancing the efficiency and profitability of your operations.

- Compact design: Its small footprint makes it ideal for use in constrained spaces without compromising performance.

With the FLEX 7 IMM robotic cell, you can do more with less. Let the experts do the work for you and elevate your production to a higher level with automation that brings greater added value and a strategic advantage.